|

True Opportunity®

|

Watch the TO Video |

Overview

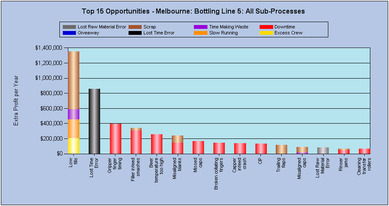

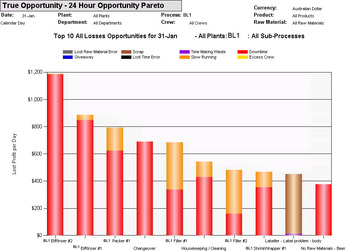

* Lost Time (Downtime, Slow Running and Time Making Waste) True Yield (Process, Department and Plant) * Lost Raw Material (Scrap, Giveaway and Rework)

|

Reporting

2. Multiple problem groupings 3. Multiple reporting units |

2. Multiple speed bottlenecks for a process 3. Multiple concurrent products on a process or sub process 4. Multiple bills of material for products 5. Variable maximum speed of bottleneck sub processes 6. Variable optimum crew size 7. Shift patterns of any complexity |

|